The Brains of Your Motorcycle: The CDI Box

The CDI box is known by many names, including pulse box, CDI module, power pack, igniter box, brain module, and if you want to get all X files, the black box. If your motorcycle was manufactured during or since the 1980s, then chances are it has a CDI box, and it’s a pretty key piece of equipment. In fact, without one it’s unlikely you’ll get your motor running, let alone get out on the highway, looking for adventure.

What Does a CDI Box Do? What is a CDI Box?

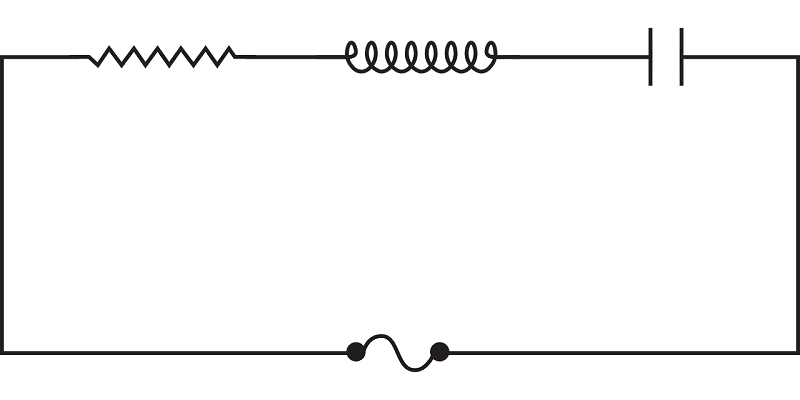

CDI stands for Capacitor Discharge Ignition. The CDI box is a key part of your motorcycle’s ignition, pretty much taking control of the ignition process. A capacitor is similar to a battery, in so far as it stores energy for use at a later time. Where it is different from a battery is that all the stored energy can be released almost instantaneously. This makes it pretty much perfect for an ignition system.

Your CDI box contains capacitors, coils, other circuitry, a trigger mechanism, and, of course, a box, which is typically black. When you go to fire up your bike, the trigger mechanism will send a message to the CDI to fire up. The CDI determines which coil to fire with the capacitors, this ignites the spark plug, and all things going to plan, bingo, your bike should roar into life.

What Is a TCI Box?

Those that don’t have a CDI box are likely to have a TCI box, which works in a very similar way. TCI stands for transistor-controlled ignition. A transistor-controlled ignition box works in a similar way to a CDI but has transistors, instead of capacitors and the processes and vulnerabilities are different.

A TCI ignition typically takes longer to ignite than a CDI ignition, and the spark voltage of the ignition generally decreases with revs. Generally, TCI’s are very economical, however, they can be affected by environmental factors, such as wind or rain.

Back In Time

The evolution of the TCI box is interesting, and credit for its invention goes to Nikola Tesla, who first filed a patent for the TCI box back in the 1890s. The patent filed by Tesla for his ignition system included a description of the box and a mechanical drawing of the device itself.

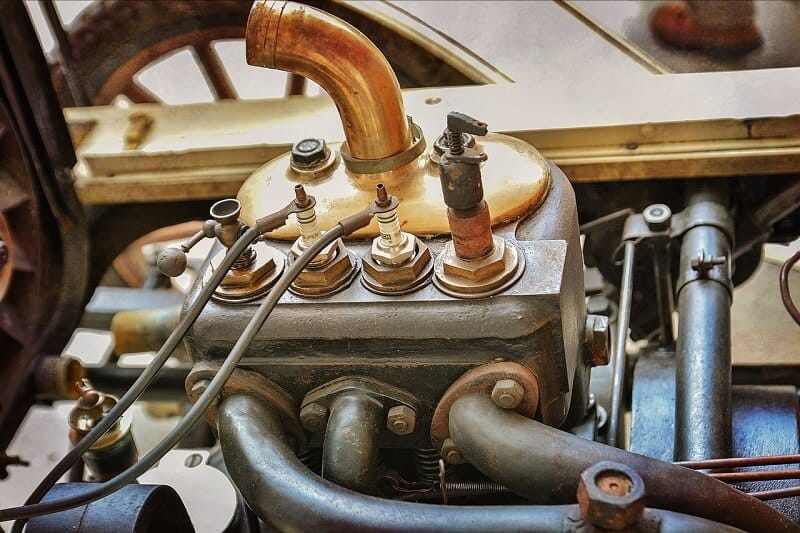

The CDI box was used for the first time on the Ford Model K in 1906, with an electronic version following in the 1950s. Unfortunately, the electronic CDI box proved exceedingly unreliable, with the earlier versions having a large number of moving parts that failed regularly due to constant movement. This included the mechanical systems that were used to fire the coils, which required cam lobes, weights, coils, and other simple mechanical devices that combined to deliver the spark at the right time.

Various scientists and research institutes have worked on the CDI box over the years to produce the modern version. The main change is the modern CDI has a lot fewer moving parts. The evolution of the CDI advanced ignition systems on motorcycles, giving manufacturers previously unrealized control over their engines. They helped deliver increased power and better efficiency and generally resulted in less maintenance being required.

Despite their relative reliability and stability, there are still times when the CDI on your motorbike can cause issues, so it’s worth knowing how to troubleshoot those issues.

Parts Of the Capacitor Ignition System

The following parts contribute to the CDI box and the ignition system. They are some of the things to troubleshoot if your ignition system is failing:

1. Flywheel

This is the magnetic part of the ignition system. The permanent magnet is horseshoe in shape and spins around the crankshaft. During the manufacturing process, the flywheel is magnetized so its own North and the South Pole are established.

2. Stator

The stator is a plate that has coils or wire placed around it. They are known as loops. These loops are responsible for delivering power to the motorbike’s lights, the battery charging circuit, and, of course, ignition.

3. Charging Coil

One of the coils that are placed around the stator is known as the charging coil. It is responsible for providing the necessary current to the flywheel, condenser, and spark plug. The charging coil produces the 6 volts of electricity that are required by the capacitor in the CDI box. Based on the momentum of the flywheel around the magnetic field, the charging coil provides a single pulse of electricity.

4. Hall Sensor

The hall sensor detects where the flywheel magnet changes from north to south pole and sends a pulse to the CDI box. This pulse triggers the CDI box to move the energy it has stored from the capacitor to the high voltage transformer.

5. Timing Mark

The timing mark is the alignment point between the engine casing and the stator plate. It’s the point where the piston is aligned to the trigger point on the flywheel and stator. The timing mark is useful as the stator plate can be rotated right to left according to the mark, which changes the CDI’s trigger point.

How Does It Integrate Together?

Still feeling a bit confused, well here’s how everything integrates together.

As the flywheel passes the charging coil, it causes the charging coil to produce 6 volts positive and 6 volts negative charge, which passes through the rectifier in the CDI box. The rectifier dumps the negative charge, while the positive charge enters the capacitor.

The charge passes from the capacitor to the condenser, which initiates the triggering point when it is fully charged. The pulse that is triggered is sent to the stator by the hall sensor where it passes multiple coils which amplify it. When it is amplified sufficiently it charges the spark plug which leads to the ignition of the engine.

How To Troubleshoot CDI Box Problems?

Any problems with ignition tend to originate in the charging system or the battery. In order to generate the current required to create the spark, it’s important that the battery is supplying the CDI box with 12 volts of current. When the engine turns over but doesn’t ignite, your first port of call is the battery, and giving it a full charge may rectify the issue.

If it does not, then you are going to need a multimeter. First, check the CDI box manual for the electrical resistance specifications for the CDI box and check them accordingly. The input wire should be the first thing you check. If it is within the specified range, move to the output wire. If this is within the range, then it’s likely the problem is with another part of the ignition system.

You May Like: How Long Does It Take to Charge a Motorcycle Battery Fully?

Information for this article was partially sourced and researched from the following authoritative Government, educational, corporate, and nonprofit organizations:

Universal Technical Institute: MOTORCYCLE IGNITION SYSTEMS: WHAT ARE THEY AND HOW DO THEY WORK?

About the author:

Michael Parrotte started his career in the motorcycle industry by importing AGV Helmets into the North American market. He was then appointed the Vice President of AGV Helmets America, total he worked with AGV Helmets for 25 years. In addition, he functioned as a consultant for KBC Helmets, Vemar Helmets, Suomy Helmets, Marushin Helmets, KYT Helmets, and Sparx Helmets.

In 1985, He is the Founder AGV Sports Group in cooperation with AGV Helmets

Click here for LinkedIn Profile: https://www.linkedin.com/in/parrotte/

Click here for complete AGV Helmet & AGVSPORT History https://agvsport.com/michael-parrotte

Click here for all AGV Sports Group Social Media information http://agvsport.info/

FM/L