Have you been in the market for a quality helmet and have come across the yellow MIPS label, but you are not sure what it stands for? Well, you needn’t worry because we have got your six! Here is a breakdown of the MIPS motorcycle helmet technology and further insights on why it has caused a paradigm shift in helmet crash proofing.

While helmet shells are pretty much the best version of themselves already, true innovation is beginning to emerge about the inside of the helmet, particularly the energy dispersing layer. Although EPS is the de facto standard, and even with technologies like MIPS to support it, there are some who believe that its best days are behind it. Is EPS obsolete? Read on to the end to find out about emergent technologies that might disrupt this space.

What MIPS Stands For — The Bookish Version

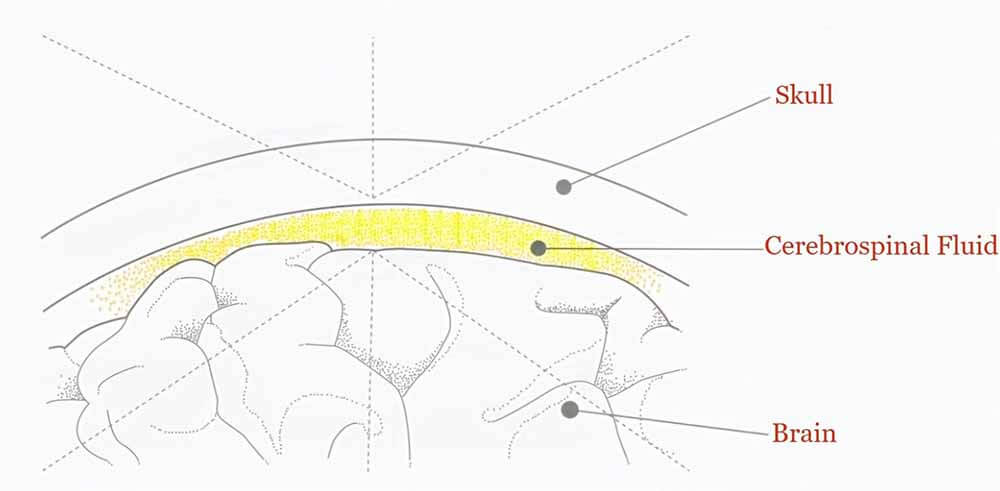

MIPS (Multi-directional Impact Protection System) technology is a proprietary and ground-breaking safety feature that gives an additional layer of protection to motorcycle helmets. Through the application of a low friction layer, the tech aims to provide rotational motion protection. This mechanism mimics the protective system used by your brain/skull and transfers it to the lid, allowing for relative motion between the head and the helmet to keep your head safe in a crash. Mmm… pretty impressive?

Yeah, MIPS Technology Is Kinda a Big Deal! But How & Where Did It All Begin?

The MIPS idea was first hatched in 1996 by a Swedish dual; Hans von Holst, a neurosurgeon, and Peter Halldin, a researcher at the Royal Institute of Technology (KTH). Nearly half a decade later, a company would be registered and named after the same acronym in 2001 with the group of specialists now having grown to five to include Svein Kleiven and two more biomechanical experts from KTH.

So, where is the innovative edge in all of this, you ask? It’s a great deal of work the northerners did here! Let’s dig a little deeper without invoking your biomechanics degree.

The Devil Is in the Details: How MIPS Sometimes Morbid Research is Helping Keep Us Safe from Traumatic Brain Injuries (TBI)

Right off the bat, MIPS was born out of a desire to create a more effective lid that could cater to the shortcomings of existing EPS technology. A simple problem with rather sophisticated solutions; one of keeping the sapient jelly in our skulls safe from shock as opposed to just keeping the skull intact.

Changing the Yard Stick

The team analyzed the blunt force trauma and the series of obtuse successive impacts consistent with most motorcycle crashes. And they sought a fix that could accommodate this information into future helmet constructions to keep the two-wheeler gang alive for longer voyages.

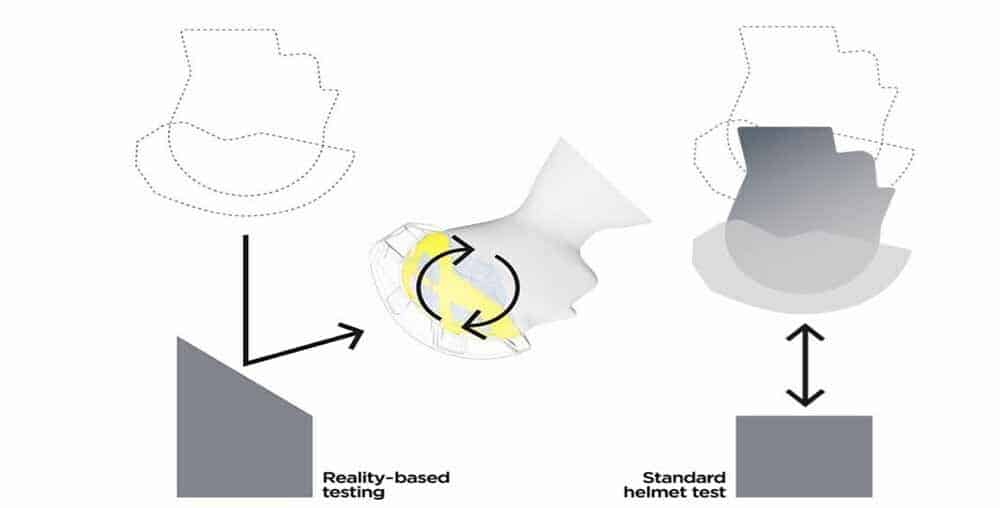

Before MIPS and, amazingly even to date, for some manufacturers, the testing standards for helmets were simply how well the lids could disperse blunt force under the standardized “drop tests”. Over the years, Dr. Holst had discovered that these were not effective as motorcycle crashes involve a burst of angled obtuse impacts, which are smaller but cause the more harmful demon of torque, causing rotational brain motion. This needed to be addressed in helmet design or the grim reaper would continue to loom over riders, snatching awesome fun-loving, and talented riders from our midst.

Yes, the ability of a helmet to absorb direct impact is an important parameter, but rarely do these occur alone in a crash. After thousands of hours of the scientific study of data derived from motorcycle crashes and consequent brain injuries, the team was able to come up with testing criteria and apparatus to measure the torsional forces acting on a rider’s head inside of a lid in a typical crash. The study was big on the relative motion between the lid and the rider’s head at any instant in a fall and the effects corresponding to the various brain and head injuries. Pretty fancy, uh?

To Keep Your Melon Intact…

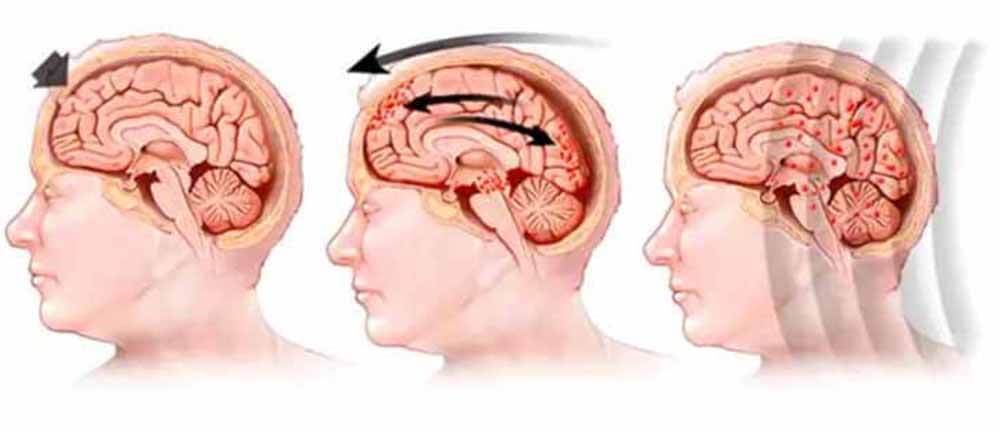

To understand the milestones achieved by Holst and the team, you must have a small background in the anatomy of the brain and have peered into a biomechanics class. The human brain is a delicate organ made of 70% water and held in a cavity that allows it to sort of swish around to prevent shock injury. It is similar to the way an egg yolk floats in egg white. Now, in a crash, the brain can twist and turn often beyond allowable limits, causing a temporary concussion or, in severe cases, Traumatic Brain Injury (TBI).

While we all appreciate not leaving DNA on the pavement, there is more to keeping you safe inside the helmet than meeting the untrained eye. In Biomechanics 101, you quickly appreciate the complexity of simple movements that your brain makes no hesitation to command.

We Just Aren’t Built to Survive 500Gs of Force…

But when it’s your brain battling monster forces to the tune of several hundred Gs, eons of evolution have not prepared it to stay put and resist being smashed against the walls into a pulp. It does its best, but there is only so much the natural cushions it has at its disposal can do.

Case in point: Severe Chronic Traumatic Encephalopathy (CTE) is prevalent among American footballers after a decade or two of random collisions with other players of comparable weight at a mere mortal speed. Chronic Traumatic Brain Injury (CTBI) is also common in boxing and occurs in about 20 percent of professional boxers between bouts. Just imagine how much more injury can be incurred in a motorcycle crash where the collisions are inelastic and against hard, often immovable objects. And yes, it’s the speed that kills because the sudden deceleration at the end wouldn’t have been necessary in the first place if you weren’t rocketing down the wrong lane.

Back to Topic, MIPS!

Now, Halldin, Holst, and Svein began investigating helmet effectiveness in relation to brain damage as earlier stated and discovered that: While helmets are effective at dispersing direct or radial impact energy, they were less effective for safeguarding against rotational (torsional) forces even though the latter were more common in a crash. This exposed riders to brain damage from sustained and successive bursts of rotational events lasting only 10-15 milliseconds each — the blink of an eye is a whopping 100 milliseconds for scale — causing brain damage.

These guys sought to isolate the skull and brain from the rapid movements of the outer helmet shell in order to mitigate such injuries and resulting deaths, albeit using dead bodies in a rather bizarre study lasting decade. And this is where their methodology gets downright morbid!

Like all “good” scientists, MIPS worked with dead bodies implanting sensors in their brains to simulate crashes and determine how to live humans experience the same. X-ray filming was used to generate a timelapse of brain movements in the short duration of impact when the most damage occurs. It wasn’t all spooky though as some cool new tech, such as laser-laden mannequin test subjects, was also used to generate the data for these models.

The Rise of MIPS

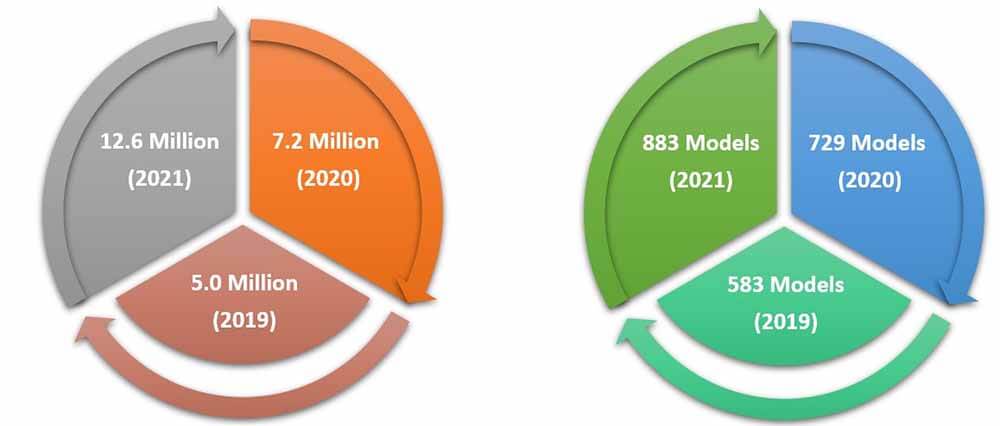

After a decade of R&D, the first-ever MIPS-equipped helmet was introduced to the market in 2009. They have since slowly gathered speed and are now taking the market by storm with millions of units selling each year. It was never about re-inventing the helmet as is demonstrated by the willingness of the company to work with various manufacturers in three major categories namely, Sports, Safety, and Motorcycle, to make all helmets in the world a notch safer.

Numbers don’t lie, there is a new wave in town. With 12.6 million total units supplied in 2021, MIPS was able to bundle its technology into a total of 883 helmet types (up from 729 units in 2020 and 583 units in 2019). Their total sales have risen from 5 million in 2019 to 7.2 million in 2020 and 12.6 million in 2021, for a total of about 24.8 million units sold so far. This number is poised to rise further in the 2022 sales year, especially now that the tech is starting to spread across multiple motorcycle helmet brands, albeit having been first introduced in a number of Bell helmets back in 2014.

MIPS does not manufacture motorcycle helmets. Instead, they collaborate with helmet manufacturers to integrate MIPS technology into their products and monitor deployment to ensure that the MIPS technology functions as intended. So, while there is no such thing as a MIPS motorcycle helmet, you may buy a lid with MIPS technology from a variety of well-known companies.

Right now, Arai, Shark, HJC, Shoei, Schuberth, and AGV don’t use MIPS in any of their products. Only Bell, Icon, and Kabuto provide MIPS helmets for street riders in the United States. In the dirt biking world, 13 companies — including Alpinestars, Fox, Answer, 509, Arctiva, Klim, Bell, KTM, Thor, Moose Racing, Z1R, MSR, and Troy Lee Designs — have MIPS-equipped helmets.

Here’s How the MIPS Motorcycle Helmet Technology Works

Rotational motion is a result of torsional energy (angular velocity) and rotational stresses (from angular acceleration), both of which affect the brain and raise the risk of severe brain injuries. The friction heat absorbs the impact, and MIPS’ safety technology distributes the pressure across a greater area of the motorcycle helmet liner.

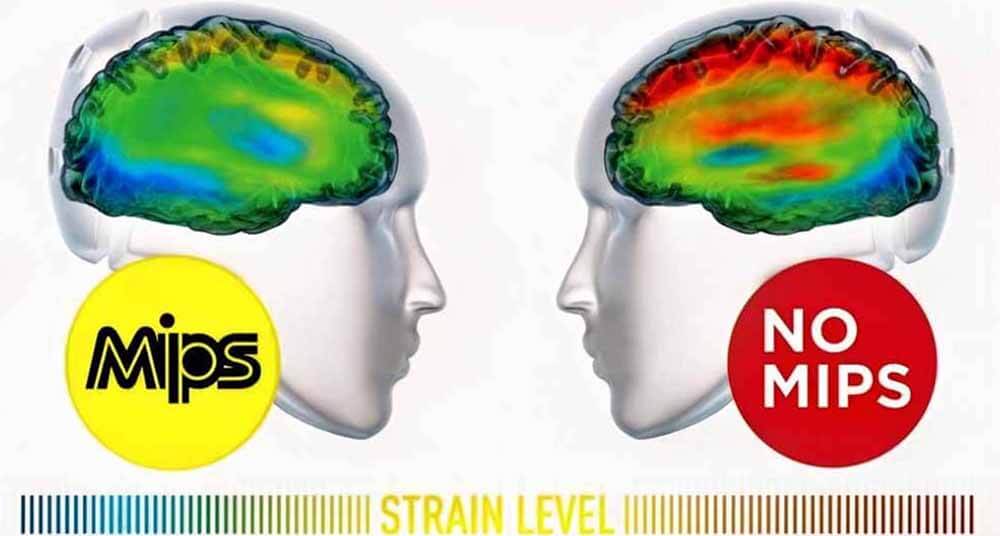

A thin, carefully designed low-friction plastic lining (the yellow patch in the Bell’s image above) rests sandwiched between the helmet’s EPS (the impact-absorbing layer, which is commonly made of polystyrene or styrofoam) and the inner cushioning that forms the helmet’s “interface” with your head. EPS absorbs, or disperses, impact energy in a crash, but the thin yellow MIPS liner allows the lid to rotate a short distance around your head, thus the most severe torsional forces (kinetic energy) are dissipated as heat.

You might argue again that a size larger helmet would achieve the same effect, but you would be misguided to think so. It is a tightrope performance to make the thin layer of MIPS operate just right. A few millimeters more movement and more severe injuries might be sustained. A snug helmet is still key to preventing other injuries, so wearing a loosely fitting one (MIPS or not) is such a bad idea, please don’t!

The MIPS technology must be both effective and virtually undetectable. A lofty request, yet the MIPS team has achieved all of these objectives after years of development.

Borrowing a Leaf from Nature

It is the culmination of years of research into the biomechanical functioning of the human brain. Cerebrospinal fluid surrounds the brain and protects it by enabling it to move somewhat when it is subjected to rotational motion as a consequence of an angled hit. The low friction layer inserted in MIPS’ safety technology replicates the function of the cerebrospinal fluid, allowing relative mobility between the head and the helmet. The company borrowed from mother nature’s masterpiece wonder organ that can think about itself, the human brain!

Nothing will happen if you experience a small amount of rotational motion in your brain. You could feel a little dizzy if you get a little more, but you’ll be disoriented momentarily but OK in the long run. However, if you have a bit more than that, you may suffer from a concussion or a serious traumatic brain injury.

Severe traumatic brain damage can present itself in a variety of ways. The axons, or nerve fibers, in your brain might shear, resulting in diffuse axonal damage (DAI), or the veins in your brain can rupture, resulting in a subdural haematoma (SDH), which is a blood collection between your brain and skull. This can cause a variety of symptoms, ranging from nausea to paralysis on one side of the body.

Testing and Implementation of the MIPS Technology in Motorcycle Helmets

MIPS’ safety system may be used in either new or existing models, giving motorcycle helmet manufacturers a competitive advantage. MIPS’ R&D lab in Stockholm, Sweden, handles most of the testing and deployment of new models. In most circumstances, a helmet manufacturer will provide a fresh design file to MIPS’ CAD (computer-aided design) engineers, who will build the CAD file for the reduced friction layer. The lids are then manufactured by their respective brands, and MIPS is sent models with the low friction layer in every size, as well as their equivalents without it. The helmets will have already passed the current testing requirements.

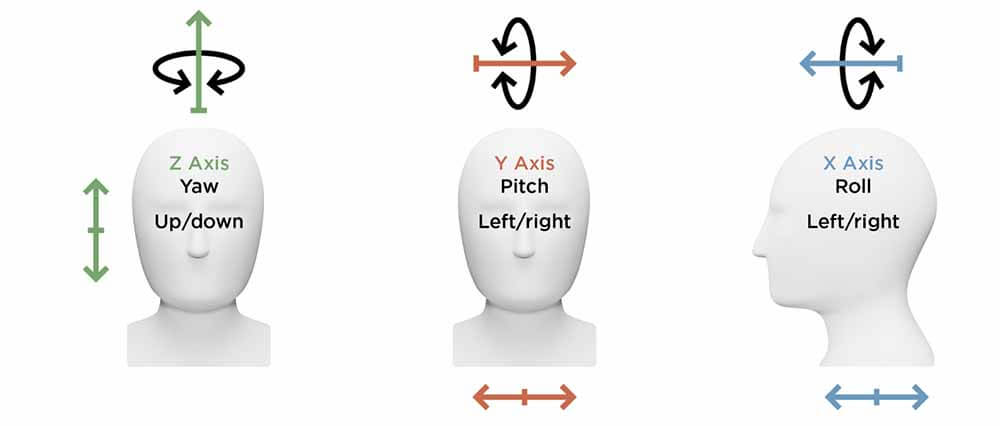

MIPS then runs intensive product testing for R&D and quality checks. As the name suggests, the helmets are designed and expected to provide maximal coverage for three anatomical axes (multi-directional impact protection) — X is forward, Y is to the side and Z is upwards – and 6 degrees of freedom (DOF), a measure of the linear and angular movement accelerations over time of a rigid body in three-dimensional space.

MIPS evaluates three separate sections in each helmet: Front, lateral, and pitched. All helmet tests are done at a 45-degree angle since studies show that the larger percentage of head impacts from motorcycle crashes are obliquely angled. Above all, having control over the initial position of the head and helmet, throughout the vertical descent to the impact anvil, is critical.

The impact data is then examined. This rigorous testing ensures that each helmet model’s MIPS’ safety system may be authorized in accordance with the MIPS standard. MIPS’ low friction layers are manufactured only once a purchase order is made, resulting in a restricted inventory of other safety system components.

When properly implemented, MIPS’ safety system has been shown in testing to minimize rotational motion in specific types of crashes when the technology is used in a helmet. It allows the head to continue moving in the direction it was following instead of remaining fixed to the impact surface by allowing a considerable slippage between the low friction layer and the helmet in the instant of impact. These slight movements significantly diminish the impulse force that is experienced by the rider and thus less severe head injury.

By the time of writing this post, MIPS facilities had tested close to 50,000 helmets.

MIPS Is Active in Three Motorcycle Helmet Categories

Road helmets, motocross helmets, snowmobiling, and helmets for the moped and scooter industry are the three categories of MIPS motorcycle helmets. MIPS believes the first two categories have a significant addressable market, while the market for moped and scooter helmets has less potential because it predominantly consists of cheaper lids in developing nations. Since 2014, MIPS has provided solutions for the road and motocross helmets, with a target market anticipated to be 28 million road motorcycle helmets and 2 million motocross helmets notwithstanding that awareness of MIPS’ technology is minimal in this field.

Motorcycle helmet sales continue to rise throughout the world, with Asia and a few emerging nations leading the way. In both Europe and the United States, MIPS has a rather consistent market and pricing trend. The industry is a significant worldwide market that is diversified by kind and area.

5 Different Types of MIPS’ Safety Systems Used in Motorcycle Helmets

MIPS continues to build product families that outline the safety aspects of different helmets and categorize each product based on its intended purpose, making it easier for bikers to pick different helmets and MIPS’ solutions. Future motorcycle helmets with MIPS’ safety solutions will be able to employ this categorization in conjunction with a new labeling system that will create consumer awareness about MIPS. This is meant to assist helmet manufacturers and end-users in choosing the optimum MIPS technology and lids for specific needs without having to trade off safety for functionality.

In January 2021, MIPS launched its new classification of MIPS’ various systems, with the aim of making MIPS-secured motorcycle helmets that match your varying needs.

- MIPS® EVOLVE: MIPS Evolve is perhaps the most extensively used MIPS’ safety system, especially in road motorcycle helmets. Its superior fit enhanced ventilation, and 1mm thick low friction layer (LFL) is integrated with a low friction coating to mitigate the twisting force of your head-on collision from particular angles toward the energy-absorbing layer. The LFL is tailored for each helmet and size.

- MIPS® INTEGRA: One of the company’s most compact, thinnest, and well-integrated systems. MIPS Integra’s varying designs (depending on the particular helmet’s properties) make for invisible integration, distinctive ventilation, and a fit that is what your preferred motorcycle helmet brand constantly tries to provide you with.

- MIPS® ESSENTIAL: MIPS Essential is a basic yet effective safety system that is ideal for entry-level motorcycle helmets. When your head is struck from specific angles, the mechanism is meant to help lessen the rotational force. The 3 elastomers, which keep the LPL positioned properly, hold the MIPS Essential in place.

- MIPS® AIR: This system is far lighter than any of the previous systems. You rarely notice it because the air flows through the motorcycle helmet. Minimum weight and maximum ventilation define MIPS Air.

- MIPS® ELEVATE: MIPS Elevate is the most advanced and revolutionary MIPS’ safety system, created with the tough conditions on a racing track in mind. It significantly reduces the rotational force applied to your head when it is struck from specific angles.

The Importance of MIPS Technology for Motorcyclists

To have a better understanding of the importance of MIPS motorcycle helmet technology, we’ll compare MIPS-equipped helmets vs. regular helmets. After all, before a lid can be marketed, it must meet safety regulations, whether or not it has a MIPS layer.

MIPS’ rotational motion reality-based helmet testing vs. standard helmet test. The elements and forces that might cause brain Injury to vary depending on the degree and location of an impact.

DOT, ECE, Snell, Sharp, and FIM testing processes only evaluate a helmet’s ability to reduce direct or linear impact, not rotational impact. MIPS, on the other hand, takes it a step further and tests for linear impact, claiming that helmets with MIPS technology may minimize the impact of rotating forces by 10%. But that’s the bare minimum, some MIPS studies show strain reductions ranging from 10.1% to 75%. The most typical is a decrease in the strain of between 25 and 30 percent. And so, the question arises — are MIPS helmets safer?

MIPS is quick to point out that it can only truly prove the system’s safety in lab settings. Every helmet is unique, every accident is unique, and each individual is unique. When the firm tests lids, they do it in a controlled environment to ensure that their technology works. They look at the verified number, although the exact figures may fluctuate across various helmets and helmet brands. The company only utilizes data from the same day when approving helmets.

So, since the MIPS pioneers assert that MIPS just lessens the effect of rotational impact and that MIPS-equipped helmets are not safer than non-MIPS helmets, the issue remains: Is MIPS worth it?

Consumers may take away the following: Riders can be certain that MIPS technology will provide them with 10% improved protection against rotating forces. This proportion, albeit small, is better than nothing when it comes to minimizing the risk of traumatic brain injuries. It might mean the difference between riding or not riding tomorrow.

A MIPS helmet is well worth the extra money for someone who is willing to pay a few dollars more for peace of mind. As of this writing, there are around 177 helmets (144 dirt bike helmets, 20 full-face helmets, and 7 dual sport helmets) on the market with MIPS fitted, of which I have had the pleasure of using one. That one street bike helmet is the Icon Airflite MIPS Stealth ($330), while Bell has the Bell Qualifier MIPS DLX ($289.95), Bell MX-9 Adventure MIPS ($349.95), and the sport-oriented Bell Star MIPS DLX ($559.95), to name a few.

When integrated into the fashionable Icon Airflite Stealth lid, the MIPS technology is virtually undetectable. There is no feedback when trying to manually wiggle the head in the helmet as it doesn’t feel much different than a non-MIPS helmet. Others may believe that a normal helmet will suffice to protect them from damage as long as it is of good quality, made by a renowned brand, and has passed safety certification. It’s worth noting that the impact of real-life collisions on a person’s head differs from the impact produced during helmet testing.

Maybe it’s time for DOT, ECE, FIM, Snell, and Sharp to reevaluate their testing protocols, and at the very least, recognize the requirement for oblique impact testing. MIPS conducts its own oblique impact testing in its lab.

8 Factors to Consider When Buying a MIPS Motorcycle Helmet to Go

Look for one with a yellow MIPS dot when purchasing your next helmet. When you see the MIPS emblem, you know it has been tested in the MIPS lab and is MIPS-approved. Here are a number of other variables to consider:

- How Large Is Your Bonce? As you learned from picking helmets 101, your head size and shape determine the lid for you. A snug fit is a must for the MIPS mechanism to operate and guarantees you walk away unscathed in the event of an unconventional and involuntary. Because MIPS inserts are now made with the helmet, you should pick one in the right size without worrying in the world.

- How Much Does a MIPS Helmet Cost? Any helmet made with extra protection and certification will reflect that in the price tag. However, you needn’t pay an arm and a leg for your MIPS-protected lid; typical MIPS helmets run the gamut with affordable items such as the Troy Lee SE4 Polyacrylite Mono Helmet going for about $245 or the Bell Star MIPS DLX Fasthouse Victory Circle Helmet costing $619.95. There are even pricier options due to size and the number of certifications, but we have exemplified that helmets can be MIPS and affordable.

- What Is Your Game? MIPS helmets aren’t created equal. There are street helmets, like the Alpinestars Supertech M10 Carbon Helmet ($599.85), which will allow you to take in the scenery on the edge of mountain goat trails in Afghanistan while the Moose Racing Agroid MIPS Helmet ($169.95) will deliver record lap times on the circuit with a moisture wicked face.

- More Air? No Problem! MIPS is designed not to stick out, but in case of a topple and only then, to be felt. If you are an avid rider, you want lighter, safer, and more fun helmets with a nice finish. Now thanks to the growing array of MIPS-protected helmets, you can enjoy a stylish personalized helmet that is also above world standards in terms of safety, performance gains, comfort, and reliability.

- Remember Safety Is Paramount. Safety! Safety! Safety! We cannot retaliate enough. Check your preferred helmet for additional credentials such as DOT, Snell, Sharp, FIM, and ECE. The more the better. Double-check sales gimmick, so you can cut through the jargon and find out the materials used and what they mean for your safety. A description could read, “High resistance material that can dissipate impact” in reference to cheap plastic and so on. Be wiser, nothing is ever as it seems, and as a rule of thumb, you do get what you paid for, especially with motorcycle safety gear and apparel.

- Come Rain and Shine! For longer rides, we recommend testing out a helmet for longer periods up to a month. It might seem like you are wasting money, but it will surely save you some agony if you plan on embarking on a long voyage. Get a helmet that is ready for the majority of the weather patterns you will likely encounter at this time of the year. Carry two if you have to or better yet, invest in a MIPS modular helmet.

- A Snug Hug! You want a helmet that fits not just for safety concerns but also to enjoy the ride.

- Weighing Your Options: With road motorcycle helmets, weight — like ventilation and safety — is important. A thin, lightweight helmet reduces neck fatigue for riders.

What is Next for MIPS? Exciting New Motorcycle Helmet Concepts You Should Be on the Lookout For

MIPS is always working on new innovations in this space as much as they have achieved tremendous success with present ones. The company poses a challenge to the entire industry to reconsider expanding its testing to include angled impacts, which are more frequent in crashes. They’re not the only ones who think so!

Since the mid-2000s, motorcycle helmets have stayed largely unchanged, with a few exceptions. The EPS liner has been perfected over the years, but there is only so much that one can iterate with the same concept of liners. However, as humans, we are always looking for new and interesting ways to do things, and the helmet business is currently at a fork in the road.

If there is a wonder product that seeks to carry on the mantle from EPS layering, it would be Koroyd. Born of an aviation disaster, Koroyd was conceptualized following the outcomes of the probe into an air crash near Kegworth of one infamous flight BD092. It emerged that cylindrical tube construction had significantly better kinetic energy absorption capacity than square tubes.

Koroyd replaces the foam on the interior of a helmet entirely with a welded-tube lattice, resulting in a lightweight helmet without compromising safety. While MIPS works in conjunction with the EPS layer to assist protect the wearer, Koroyd aims to completely replace the EPS layer. Since it is made out of hollow tubes, it allows for far better heat transmission than EPS foam, letting the helmet’s vents perform much more efficiently to keep you cool.

Klim and Thor Racing (both MIPS partners) are two of Koroyd’s key motorcycle helmet partners, and they also provide their own brand of body armor inserts for typical back, shoulder, and elbow protector armor pockets in daily motorcycle clothing.

Elastomeric Isolation Damping (EID) is another big invention that has only begun to come on the market and has been developed to function with both MIPS and Koroyd, or on its own fully. In the most basic terms, helmet maker 6D, which claims its proprietary ODS (Omni-Directional Suspension) technology, shrunk a heavy-duty industry idea and placed it between the shell and the EPS liner in a helmet.

These dampers, like MIPS, are designed to cushion the first few milliseconds of rotational impact. They have a benefit over MIPS in that they are also purposefully compressible, similar to how your motorcycle’s front fork suspension works. It absorbs impact energy, safely dissipates it, and then recovers.

Information for this article was partially sourced and researched from the following authoritative Government, educational, corporate, and nonprofit organizations:

Effect of helmet design on impact performance of industrial safety helmets

About the Author:

Michael Parrotte started his career in the motorcycle industry by importing AGV Helmets into the North American market. He was then appointed the Vice President of AGV Helmets America, total he worked with AGV Helmets for 25 years. In addition, he functioned as a consultant for KBC Helmets, Vemar Helmets, Suomy Helmets, Marushin Helmets, KYT Helmets, and Sparx Helmets.

In 1985, He is the Founder of AGV Sports Group, Inc. cooperation with AGV Helmets in Valenza Italy

Click here for LinkedIn Profile: https://www.linkedin.com/in/parrotte/

Click here for complete AGV Helmet & AGVSPORT History https://agvsport.com/michael-parrotte

Click here for all AGV Sports Group Social Media information http://agvsport.info/

M/A